25 Jul Air Carbon Arc Gouging. What is it, how does it work and what are the advantages?

What is Air Carbon Arc Gouging, how does it work, and what are the advantages you ask. Let’s find out.

What is Air Carbon Arc Gouging?

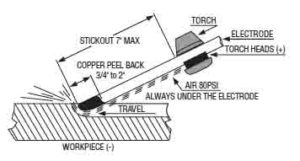

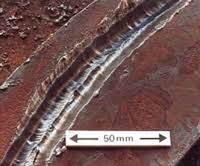

Air carbon arc gouging is a process of removing metal by means of heat generated from a carbon arc. The process uses a carbon/graphite electrode, compressed air and a standard power source. The intense electric arc used between the tip of a carbon electrode and a metal work piece cuts and melts the work piece. The arc is initiated by striking the electrode tip on the surface of the work piece. Then compressed air is used for blowing the molten metal thoroughly from the metal surface. The metal is only cut or gouged along the airflow direction. This process is simple to apply. The main purpose is to remove defective or old welds in order to repair or dismantle equipment. Manual metal arc (MMA) welding equipment can be used when air carbon arc gouging however unlike MMA the tip is not withdrawn to establish length.

How Does it Work?

A power source with high voltage capacity is required. DC (direct current) is most suitable and preferred for steel and stainless steel. AC (alternating current) can also be used however works better for case iron, copper and nickel alloys. The power source must have a constant current output characteristic otherwise the high voltage current can cause the electrode tip to “explode” when touched to the piece being worked on.

A compressed air line, up to 100psi or separate bottled gas supply, around 35psi, are used. There are no advantages in using higher pressures as they may not remove the molten metals properly.

The electrode is a graphite-carbon rod with a cooper coating. The cooper coating reduces electrode erosion. By using the correct electrode diameter required for the width and depth of the gouge, cutting can be precisely controlled and material waste is kept to a minimum.

What Are the Advantages?

1-The air carbon arc cutting process can be performed on the work piece in all directions.

2-The temperature of the surrounding area of the cut material does not reach the maximum as the metal is quickly removed after melting.

3-The process can gouge or cut almost all common metals.

4-As most of the surface carbonized materials, near the cut, are removed during a cleaning process the scraps can be re-melted.

So there you have it, air carbon arc cutting is the process of removing metals from the work piece, using heat from a carbon arc, compressed air and a power source, that is highly effective with minimum waste.

If you require any repairs that would require air carbon arc cutting give Kaymor a call at 780-538-2623 and ask for Dave.